Laboratory has at its disposal modern testing equipment, consisting of:

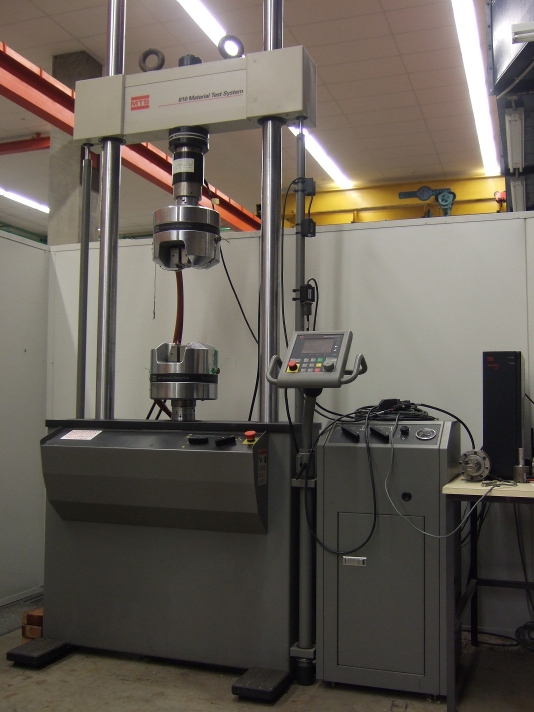

- Servohydraulic testing machine MTS 810 of a maximum load being 100 kN, which allows to perform a broad range of mechanical tests - static and dynamic - of various materials. o maskymalnym obciążeniu 100 kN pozwalająca na przeprowadzenie szerokiego zakresu badań mechanicznych różnych materiałów zarówna statycznych jak i dynamicznych.

- The testing machine MTS 810 is equipped with the controller TestStarIIs, which is a fully automated, numerical controlling system. It controls one channel operations (servo-motor together with sensors) in a closed feedback loop. The TestStarIIs uses the graphite computer environment by means of which it is possible to programme the tests and record the data. Processes important for investigations such as servo-motor control, piston movements and data gathering are performed by the controller and its software.

- The TestStarIIs system software, working in the operation environment Microsoft Windows NT on the PC computer class.

- The actual software designed on the bases of the most modern microprocessor technologies, present in the controller.

- An optional control panel, allowing a manual control of the hydraulic pressure and controller placement.

- The Laboratory has at its disposal the bench polariscope, for photo-elastic examinations in the passing through light, the portable polariscope of the Vischay Company used for photo-elastic examinations in the reflective light and the mechanical extensometer allowing to calibrate photo-elastic materials..

The controller consists of three basic elements:

Fig. 1 Testing machine MTS 810.

Fig. 1 Testing machine MTS 810.